Tech-driven manufacturing key for growth

Core technologies to catalyze country's shift toward high-quality development

China's steadfast commitment to pursuing advanced manufacturing will help the country move up value chains, sharpen its edge amid global competition and navigate external headwinds in order to ensure sustainable economic growth, experts and corporate executives said.

Highlighting the crucial role of cutting-edge technologies in empowering China's sprawling industrial economy, they said that more policies are likely to be in the pipeline to make manufacturing higher-end, smarter and more eco-friendly.

As 2025 marks the last year of China's 14th Five-Year Plan (2021-25), the nation's emphasis on mastering core technologies in manufacturing will accelerate the transition of its development paradigm from quantity-driven to quality-driven during the 15th Five-Year Plan (2026-30) period, they added.

During his visit last month to Luoyang Bearing Group in Henan province, President Xi Jinping said: "China has always adhered to the path of developing the real economy. From the past reliance on imported matches, soap and iron, to now becoming the world's largest manufacturing country with the most complete industrial categories, we have taken the right path."

China must continue to strengthen its manufacturing sector, adhere to the principles of building self-reliance and strength, and master core technologies in key fields, he added.

Luo Zhongwei, a researcher at the Chinese Academy of Social Sciences' Institute of Industrial Economics, said that Xi's emphasis on manufacturing showed that a modern industrial system will be key to China's economic development over the next few years, and will have a profound impact.

"In the face of growing external risks, 'Made in China' needs to be backed by a stronger industrial system," Luo said.

According to Luo, countries around the world have all realized the importance of manufacturing, and China will not repeat the mistakes of some developed countries that took the path of deindustrialization and now have no choice but to work very hard to bring manufacturing back.

"I believe that manufacturing will be a key priority in China's upcoming 15th Five-Year Plan," Luo said.

Hong Qunlian, a researcher at the National Development and Reform Commission's Chinese Academy of Macroeconomic Research, said, "Manufacturing is the focal point of competition among major powers and technological supremacy. Nurturing strategic advantages for the future fundamentally relies on the high-quality development of our manufacturing industry."

"Promoting tech-driven industrial upgrading is paramount for China's real economy over the next five years. And achieving breakthroughs in critical technologies is not optional, it is essential, as we still face challenges in these areas," Hong added.

Zhang Li, president of the China Center for Information Industry Development, said, "China's economy has historically relied on the real economy, and it is through this foundation that it will continue to progress."

China has been the world's largest manufacturing country in terms of output for 15 consecutive years, and it ranks first globally in the production of over 220 industrial products, according to the Ministry of Industry and Information Technology, China's top industry regulator.

"Boasting such a complete industrial system, China provides rich application scenarios and enormous market potential for technological innovation, as well as solid support for the development of emerging industries," Zhang said.

Fresh model

Unlike some Western countries that pursued an excessive shift to services at the expense of manufacturing, China's push for new industrialization features efforts to stabilize the ratio of manufacturing business in China's GDP and does not simply phase out traditional industries, experts said.

Hong, from the Chinese Academy of Macroeconomic Research, said, "We need to coordinate the upgrading of traditional industries with the cultivation of emerging ones."

According to the ministry, China's traditional industries are vast and account for over 80 percent of the manufacturing sector.

"Traditional industries should not simply be labeled as 'low-end industries' and phased out. We must accelerate their development toward higher-end, smarter and greener directions, allowing them to 'blossom anew'," the ministry said last year.

Meanwhile, the ministry is also stepping up the push to promote the application of artificial intelligence in industrial sectors.

Li Lecheng, minister of industry and information technology, chaired a meeting in Beijing last week, outlining a comprehensive strategy to accelerate AI technological innovation and integrated application, thereby positioning AI as a core driver for China's new industrialization.

Companies are moving fast in this direction. In May, a fleet of 100 autonomous electric mining trucks began operation at an open-pit mine in the Inner Mongolia autonomous region, marking the largest-scale application of such vehicles globally.

As coal remains a key pillar of China's energy security, China Huaneng Group has partnered with XCMG Machinery and Huawei Technologies to develop a low-carbon, unmanned, intelligent transportation system.

These unmanned trucks can annually replace over 15,000 metric tons of diesel fuel, resulting in a reduction of 48,000 tons of carbon dioxide emissions. Each truck can reach comprehensive transport efficiency of 120 percent of manual operations, and it can operate continuously at temperatures as low as minus 40 C, Huaneng said.

Zhang Ping'an, CEO of Huawei Cloud, said, "This project demonstrates how 5G, cloud, AI and new energy technologies can solve core industry challenges in establishing a new paradigm for global mining."

Strategic shift

Denis Depoux, global managing director of market consultancy Roland Berger, said that China is making a strategic shift toward modern and sustainable economic growth, which "relies on factors such as advanced manufacturing, decarbonization and growing innovation prowess".

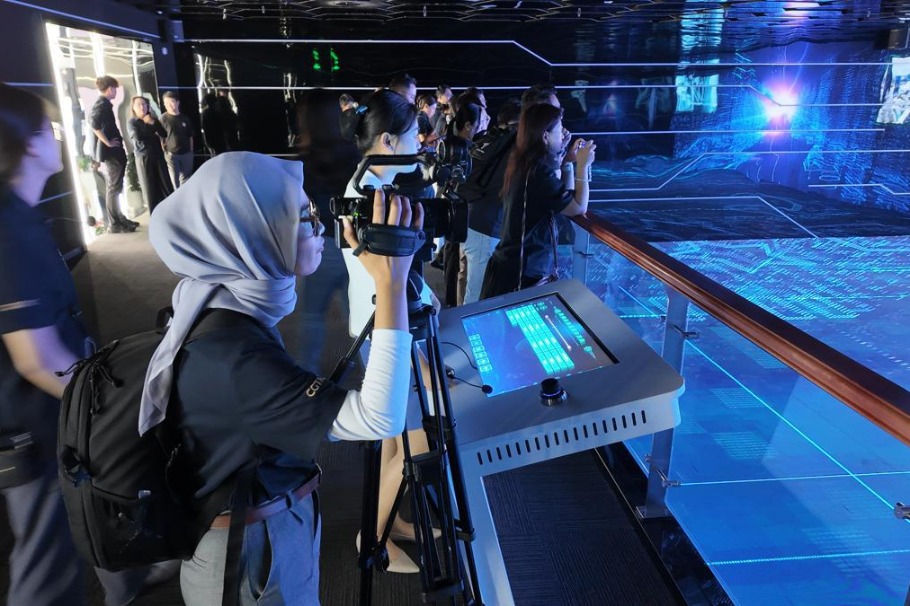

China dominates the Global Lighthouse Network list, a project launched by the World Economic Forum in collaboration with consultancy McKinsey & Co to track advanced manufacturing plants, known as "lighthouse factories", which apply state-of-the-art digital technologies.

China is now home to 79 "lighthouse factories", the highest number of any country and accounting for more than one-third of the global total.

Meanwhile, China has ever-stronger equipment manufacturing capabilities, as reflected in the fact that annual production of new energy vehicles passed the milestone of 10 million units on Nov 14, making China the only nation to realize such an achievement, the ministry said.

It took only six years for this figure to grow from 1 million to 10 million, showcasing the nation's unwavering commitment to innovation-driven development.

"Innovation stands as a pivotal force propelling the high-quality advancement of the manufacturing sector, and companies are increasingly assuming central roles in driving innovation," said Li Jinghong, an academician of the Chinese Academy of Sciences and a professor at Tsinghua University.

Ma Jun, senior vice-president of Volvo Group and president of Volvo (China) Investment, said: "We see great potential in China's AI growth. With its vast market and diverse application scenarios, China provides a unique space for AI innovation. I look forward to seeing more creative AI solutions in the transportation and infrastructure sectors, to help reduce logistics costs further and support sustainable development in China and globally."

masi@chinadaily.com.cn